Mechanical Assembly

Our mechanical assembly services provide comprehensive solutions for complex component integration. We specialize in light assembly operations including the installation and testing of Helicoils, Slimerts, Keenserts, Lee Plugs, Lee Restrictors, Rosan Fittings, and a variety of specialized studs and pins.

Every assembly undergoes inspection and testing procedures to ensure optimal performance and reliability. Our experienced technicians follow strict quality protocols to deliver components that meet the most demanding specifications.

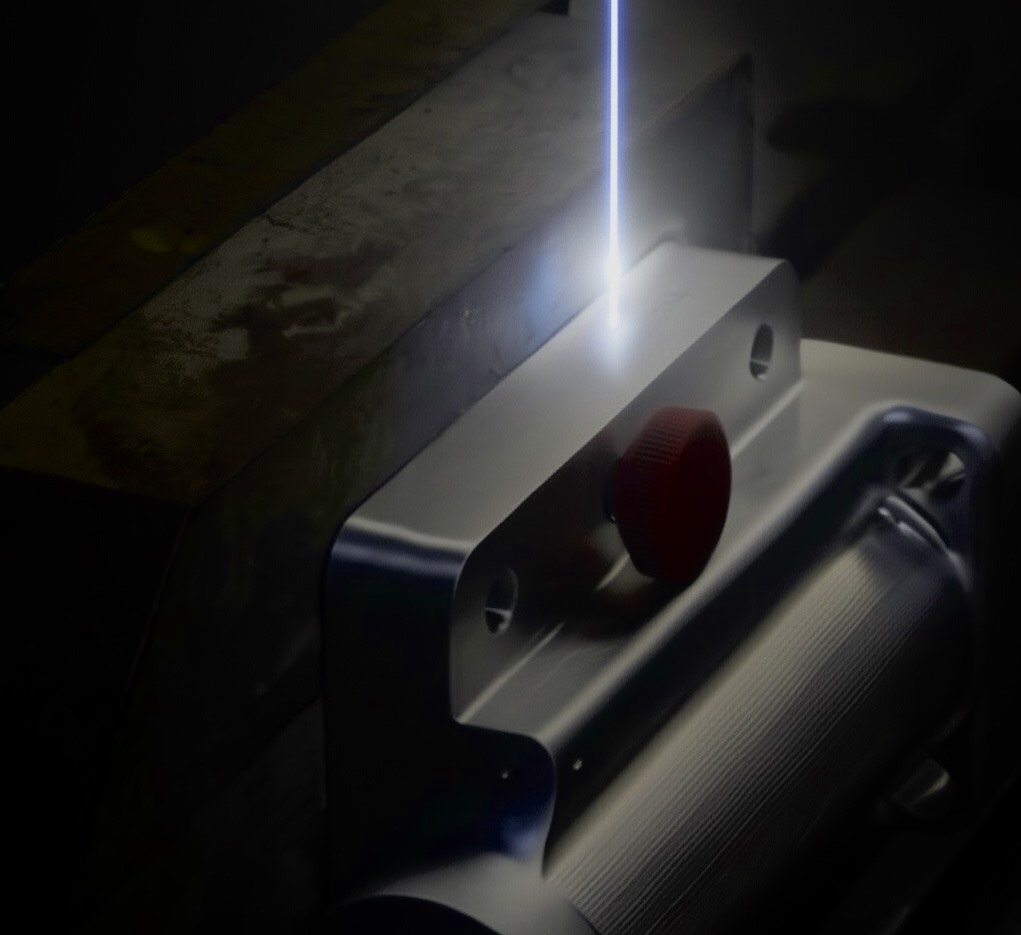

Precision Installation

Expert installation of threaded inserts, fittings, and specialized hardware

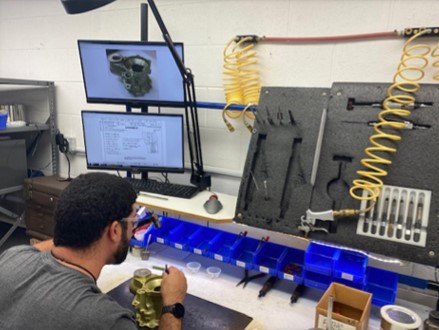

Quality Inspection

Comprehensive inspection protocols ensure every component meets specifications