Norris Precision's Lean Manufacturing initiatives ingrain the discipline, daily practices, and tools needed to establish and maintain a persistent, intensive focus on processes that are measured to expected results. They identify value added activities in the value stream to eliminate waste and improve manufacturing and business processes. Norris Precision's Lean culture utilizes the disciplines of Leadership Standard Work, Visual Controls, and Accountability processes to drive Kaizen projects that eliminate waste while increasing capacity and reducing lead time.

Manufacturing Excellence

Innovative solutions for aerospace, military, and medical industries with precision at our core

Precision Machining

At Norris Precision, we specialize in high-precision CNC machining for aerospace, military, and medical applications. Our state-of-the-art equipment and expert machinists deliver components with exceptional accuracy and quality.

Our facility houses multiple 5-axis machining centers, allowing us to manufacture complex geometries with extreme precision. Each machining cell is optimized for efficiency and quality, ensuring consistent results across production runs.

With decades of experience in precision manufacturing, we've developed proprietary processes that enable us to achieve the tightest tolerance consistently. Our technical expertise combines with cutting-edge equipment to deliver components that meet the most demanding specifications.

5-Axis Machining

Complex geometries with superior surface finishes for demanding aerospace applications.

3-4 Axis Machining

Accurate multi-surface machining for aerospace parts requiring consistent, tolerances.

High-Speed Machining

Efficient production with reduced lead times while maintaining exceptional quality.

Automated Processes

Consistent quality with robotic handling and automated inspection systems.

Metal Finishing

Norris Precision Mfg. offers the highest quality Nadcap certified chemical processing. We offer chromic and sulfuric anodize, chem-film, and passivation processed to a wide variety of government, military, and customer specifications. Having this capability in-house greatly reduces manufacturing lead-time while improving quality by having complete process control to maintain dimensional integrity.

Anodizing

Chromic and sulfuric anodizing processes that provide corrosion resistance and enhanced surface properties for aerospace and military applications.

Chemical Conversion Coating

Chem-film treatments that create protective conversion coatings, ensuring optimal adhesion for paint systems and corrosion protection.

Passivation

Precision passivation services that remove free iron and enhance the natural corrosion resistance of stainless steel components.

New Metal Finishing Facility

Expanding our capabilities with a dedicated finishing center for enhanced capacity and faster turnaround times.

Learn More About Our Capabilities

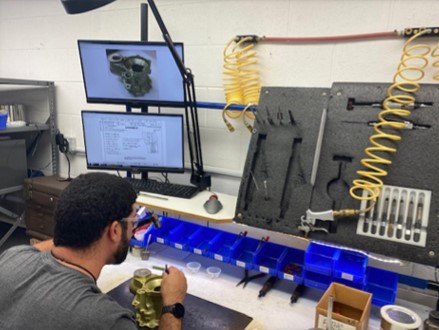

Assembly & Testing

In addition to Norris Precision's machining capabilities, we offer a full range of value-added assembly options to provide our customers with complete, ready-to-install components and subsystems, saving time and ensuring quality.

Precision Assembly

Complete component and subsystem assembly with quality control at every step.

Hydrostatic pressure testing

Verifies structural integrity and leak resistance using controlled high-pressure water testing.

Documentation

Detailed documentation and traceability for all assembly and testing processes.

Lean Manufacturing

Ongoing optimization of processes to eliminate waste and improve efficiency.

Identifying and eliminating non-value-added activities throughout production.

Minimizing inventory while maintaining production flow and meeting delivery requirements.

Smart manufacturing technologies that improve visibility and decision making

Want to see more of our capabilities? Explore how we bring precision and quality to every project.

View More Capabilities